-

Remove

-

Recycle

-

Reuse

-

Reduce

-

Flow Battery: Renewable and StorageA flow battery, is a type of electrochemical cell where chemical energy is provided by two chemical components dissolved in liquids contained within the system and separated by a membrane. Ion exchange (accompanied by flow of electric current) occurs through the membrane while both liquids circulate in their own respective…Reduce

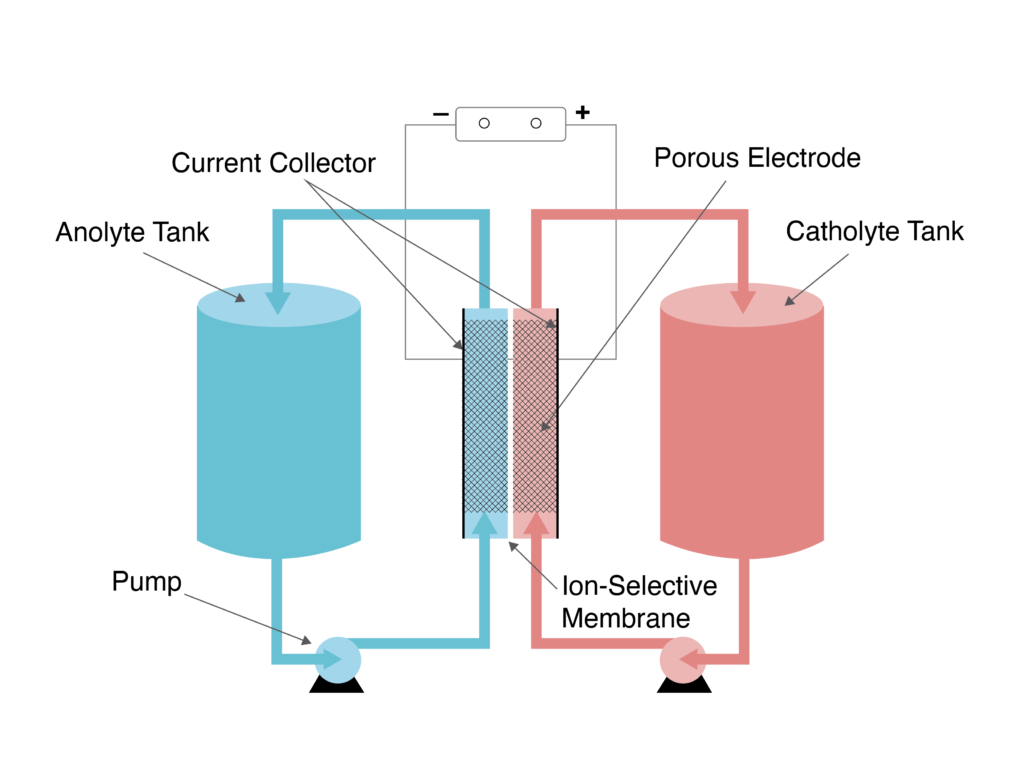

A flow battery, is a type of electrochemical cell where chemical energy is provided by two chemical components dissolved in liquids contained within the system and separated by a membrane. Ion exchange (accompanied by flow of electric current) occurs through the membrane while both liquids circulate in their own respective space. Cell voltage ranges, in practical applications, from 1.0 to 2.2 volts.

- The specific processes: A flow battery may be used like a fuel cell (where the spent fuel is extracted and new fuel is added to the system) or like a rechargeable battery (where an electric power source drives regeneration of the fuel). While it has technical advantages over conventional rechargeable, such as potentially separable liquid tanks and near unlimited longevity, current implementations are comparatively less powerful and require more sophisticated electronics.

- Primary objective of the technology is to store energy from renewable energy sources such as solar power to later generate power + electricity when needed. The project will begin in Saudi, it will manufacture redox flow storage systems for utility-scale renewables projects, telecom towers, mining sites, remote cities and offgrid locations.

- German production equipment provider Schmid and Saudi chemical group Sabic are planning to begin activities at a new factory in Saudi Arabia, with production being expected to begin in 2021.

More informationWhere is it deployed?

More informationWhere is it deployed? -

Injecting Oxygen into Oil reservoirs to extract HydrogenHydrogen is a carbonless fuel which creates no CO2 when used. Proton technologies, a Canadian oil company that is affiliated with the University of Calgary has a way to make clean hydrogen at an anticipated production cost below $0.30 US per kg with a lower carbon intensity than wind or…RemoveReduce

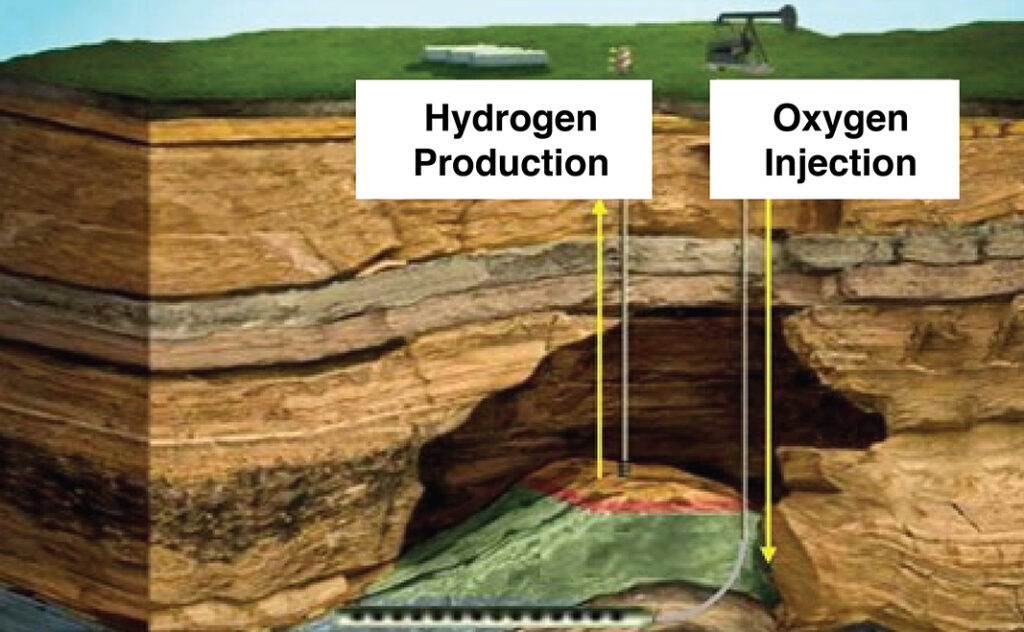

Hydrogen is a carbonless fuel which creates no CO2 when used. Proton technologies, a Canadian oil company that is affiliated with the University of Calgary has a way to make clean hydrogen at an anticipated production cost below $0.30 US per kg with a lower carbon intensity than wind or solar to electrolysis. The abandonment of Oil fields in the company’s perception is not due them being empty, rather they have reached their economic limit even though much oil remains in the ground. The company’s process to capture remaining oil involves injecting liquid oxygen into oil reservoirs. This triggers reactions that produce hydrogen. Then a downhole hydrogen filter (membrane) is used where it allows only hydrogen to come into the production well and up to the surface, hence leaving all carbon in the ground. The cost structure is low because late-life oilfields become the company’s reaction vessel which already contains decades of fuel.

- In terms of transporting hydrogen, It could be moved by trucks, by rail, by pipelines as a gas and as a liquid, or it could be incorporated into chemicals such as ammonia. If the production cost of hydrogen is lower than natural gas, baseload electricity and blending into natural gas systems are attractive and there would be an incentive to use hydrogen generators due to the large and evidently proven markets that would purchase this commodity as infrastructures and customer demand already exist.

More informationWhere is it deployed?

More informationWhere is it deployed? -

Hydrogen to Ammonia: (Green Ammonia)Green ammonia uses renewable energy instead of natural gas or coal for producing hydrogen; hence, it is an effective way to reduce greenhouse emissions. The electrochemical Haber-Bosch process is known to produce ammonia without any greenhouse gases. And Green ammonia is a reference to ammonia that has been produced through…Reduce

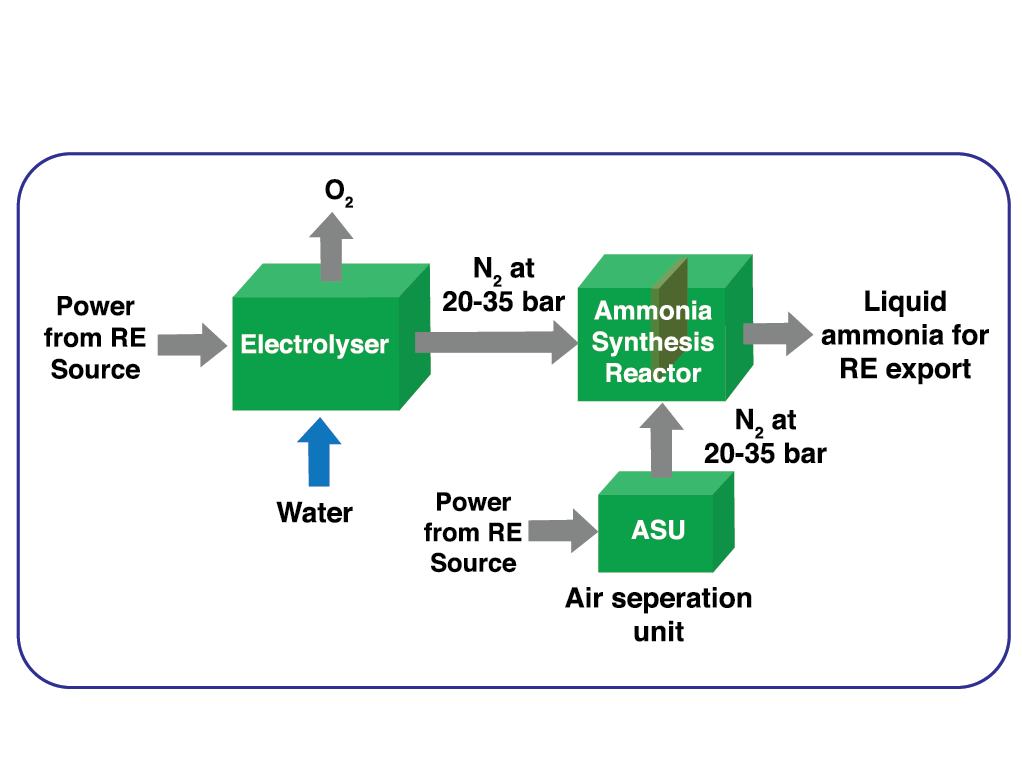

Green ammonia uses renewable energy instead of natural gas or coal for producing hydrogen; hence, it is an effective way to reduce greenhouse emissions. The electrochemical Haber-Bosch process is known to produce ammonia without any greenhouse gases. And Green ammonia is a reference to ammonia that has been produced through a process that is 100% renewable and carbon-free. Reducing the carbon dioxide emissions during the production process is essential to achieve zero emission targets. The industrial advantages of green ammonia is that it could be utilized as a main ingredient for cleaning materials, a fuel for engines, a catalyst for power and a refrigerant for cooling systems.

- In terms of processes, One way of making green ammonia is by using hydrogen from water electrolysis and nitrogen separated from the air. These are then fed into the Haber process that is powered by sustainable electricity. In the end, green ammonia is produced and utilized for transportation purposes in the form of fuel for fuel cells vehicles and in the form of feedstock to produce green fertilizer.

- Because green ammonia is a pungent gas it is key and is widely used to make agricultural fertilizers

More informationWhere is it deployed?References

More informationWhere is it deployed?References -

Alternative chemistry batteriesFor decades, the world has been utilizing Lithium-ion batteries for power and storage. In recent years, Tesla has concentrated vastly on this technology and has shown commitment by building a large factory producing state of the art batteries that will replace car batteries, Powerwalls and Powerpacks for homes and businesses. But because…Reduce

For decades, the world has been utilizing Lithium-ion batteries for power and storage. In recent years, Tesla has concentrated vastly on this technology and has shown commitment by building a large factory producing state of the art batteries that will replace car batteries, Powerwalls and Powerpacks for homes and businesses. But because battery tech is cutting-edge, breakthroughs for alternatives are practically inevitable. Examples of worthy technologies that have market potential are the following:

- Aluminum-Ion batteries have been recently been introduced at Graphene Manufacturing Group (GMG). This manufacturing company has constructed an aluminum battery that could reduce charging times. In smartphones, the battery could take a full charge in just 60 seconds and in cars, the battery could charge in minutes. With an aluminum negatively charged cathode and a graphite anode, it’s safe, lightweight and entails improved energy density.

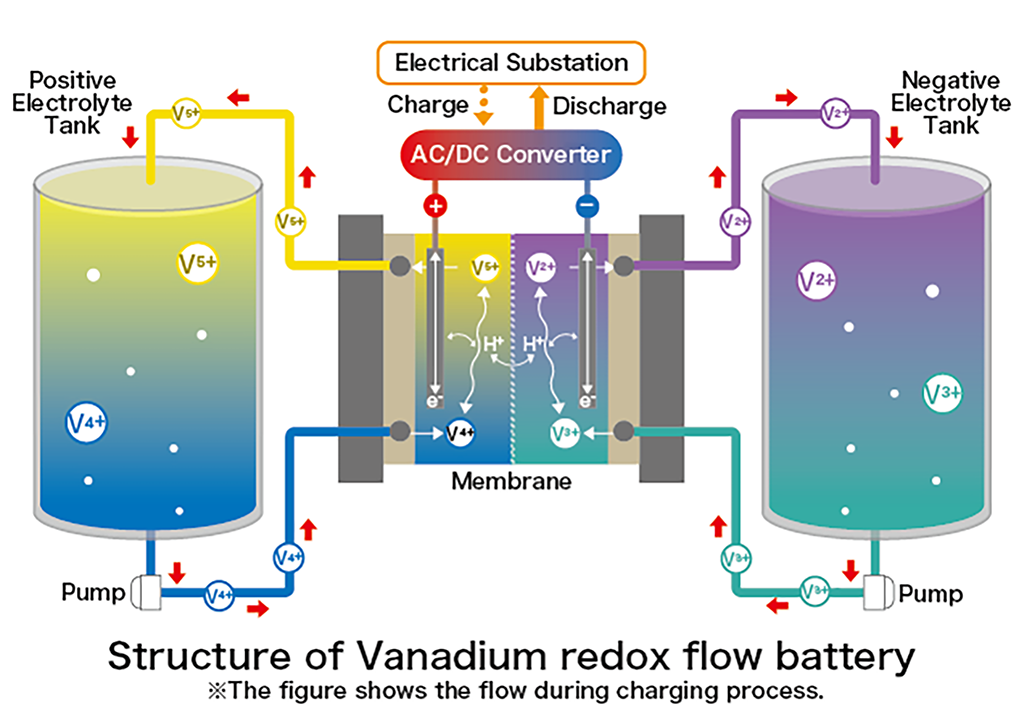

- Redox flow batteries are the future, according to the Department of Energy’s Pacific Northwest National Laboratory. These new dual-liquid batteries may have potential in the market but still require few enhancements. By adding hydrochloric and sulfuric acid to the mix, researchers have produced prototype batteries with 70% more energy density than a lithium-ion battery of similar proportions. They are squarely aimed at the Powerpack market and could store energy from wind and solar farms. Their design is aimed to offer up to four times the lifespan and much greater storage from renewable energy sources. If commercialized, these batteries should be able to provide remote communities with constant power and replace electrical sub-stations. They could also propel a car up to 1,000 miles on a single charge and make them faster. Although when it comes to global vehicle performances currently there are limitations.

More informationWhere is it deployed?

More informationWhere is it deployed?