-

Remove

-

Recycle

-

Reuse

-

Reduce

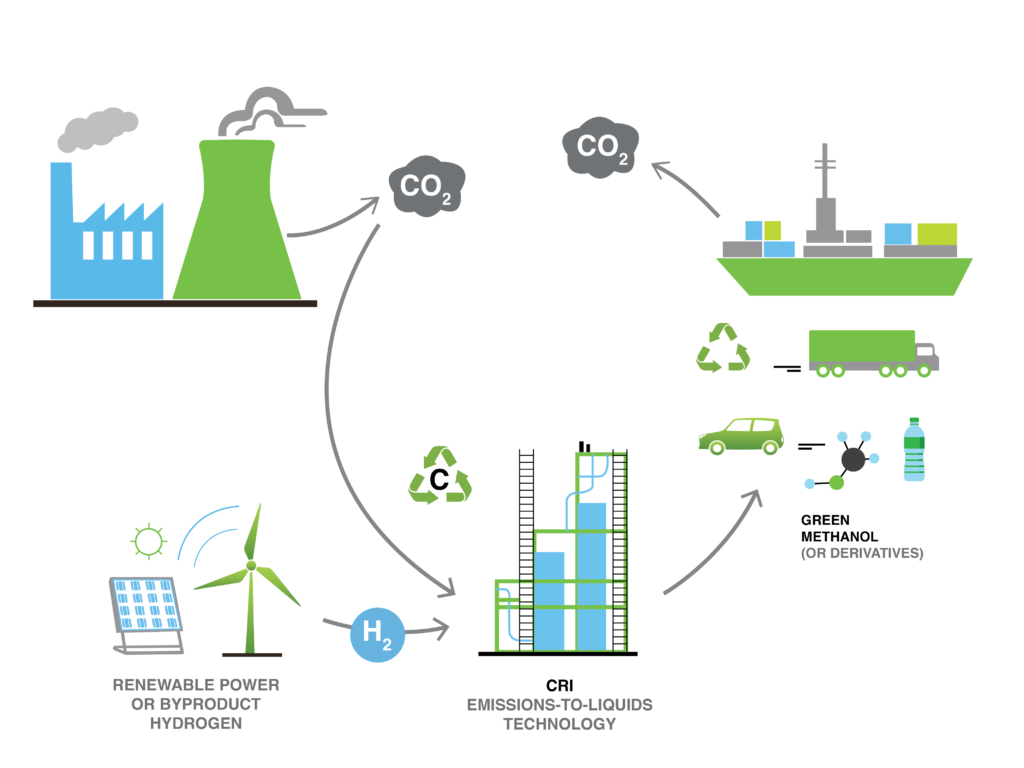

Carbon to Chemicals

-

CO2 Utilization (CO2 to Methanol)The underlying technology is based on catalytic/ adsorbent process for producing high purity CO2.The carbon dioxide hydrogenation process works by decomposing water to create a hydrogen gas using renewable energy, which then bonds with the carbon dioxide on the surface of the catalyst to create methanol. The process essentially converts greenhouse gases to fuels that emit carbon dioxide when burned. An…Recycle

The underlying technology is based on catalytic/ adsorbent process for producing high purity CO2.The carbon dioxide hydrogenation process works by decomposing water to create a hydrogen gas using renewable energy, which then bonds with the carbon dioxide on the surface of the catalyst to create methanol. The process essentially converts greenhouse gases to fuels that emit carbon dioxide when burned.

- An example of a catalyst would be Cu. The catalyst encourages high selectivity a larger percentage of the products go to creating methanol. Methanol is used to create many materials and fuels, from adhesives and plywood subfloors to water bottles, wrinkle-resistant shirts and diesel fuels. It is also a chemical used in making antifreeze, windshield washer fluid, solvents and other products.

- Primary objective of the technology is to purify up to 0.5 Mtpa. The CO2 can be used for methanol, urea and food grade application. The underlying technology is based on catalytic/ adsorbent process for producing high purity CO2.

More informationWhere is it deployed?

More informationWhere is it deployed?